K&C Test Planning

Planning a K&C Test to Meet Your Goals

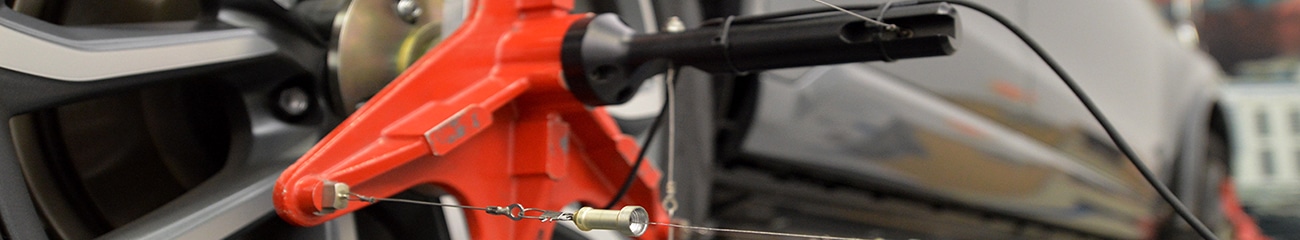

Suspension kinematics and compliance testing is incredibly powerful when planned well. At Morse Measurements we work to get the customer answers to their specific questions. Oftentimes these answers can be found through a standard series of tests. If not, we have the experience required to design a unique series of tests, or even develop new tests, to get the answers. We use our 15 years of experience to help you with your K&C test planning.

In the production vehicle and motorsports industries there are many common objectives that customers have for K&C testing. Let’s work through a few of those objectives and see how we can plan tests to reach them.

Production Vehicle Test Planning Objectives

Planning a K&C Test to Meet Goals

Suspension kinematics and compliance testing is incredibly powerful when planned well. At Morse Measurements we work to get the customer answers to their specific questions. Oftentimes these answers can be found through a standard series of tests. If not, we have the experience required to design a unique series of tests, or even develop new tests, to get the answers. We use our 15 years of experience to help you with your K&C test planning.

n the production vehicle and motorsports industries there are many common objectives that customers have for K&C testing. Let’s work through a few of those objectives and see how we can plan tests to reach them.

Production Vehicle Test Planning Objectives

Goal: Measure the suspension data required for an accurate CarSim® model

Goal: Benchmark a competitor’s vehicle to evaluate their design decisions

Goal: Evaluate the effect of an aftermarket suspension component

Goal: Evaluate prototype build

Did you know?

You can get K&C data without vehicle sourcing, shipping, or test planning.

Motorsports Test Planning Objectives

Motorsports Test Planning Objectives

Goal: Generate baseline data

Goal: Simulation Validation

Goal: Evaluate effect of part changes

Goal: Validate suspension performance for a specific track

Goal: Compare two different cars

Call Now: 704.638.6515

Call Now:

704.638.6515

1163 Speedway Blvd.,

Salisbury, NC 28146

Phone: 704.638.6515

Fax: 704.638.6516

Info@MorseMeasurements.com

© 2024 Morse Measurements | Powered by Miller Davis

1163 Speedway Blvd., Salisbury, NC 28146

Phone: 704.638.6515

Fax: 704.638.6516

Info@MorseMeasurements.com

© 2024 Morse Measurements | Powered by Miller Davis