What is K&C Testing?

Kinematics and Compliance (K&C) Testing:

Kinematics and compliance testing (K&C testing) is a type of quasi-static suspension testing that applies realistic loads and displacements to a vehicle’s chassis and tires to determine suspension geometry and stiffness characteristics.

Let’s break that down.

K&C testing is a special type of vehicle suspension testing.

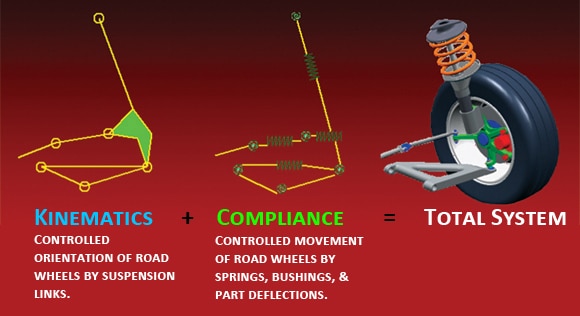

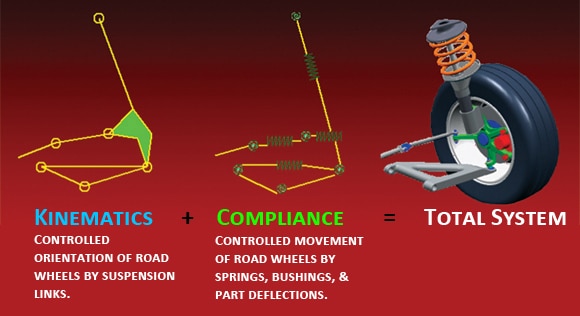

The “K” stands for Kinematics – This is the suspension geometry (toe, camber, etc.). The “C” stands for Compliance – This is the suspension stiffness (i.e. how far do things bend when road loads come up through the tires).

Measuring suspension kinematics and compliance characteristics is very difficult without the proper tools. Imagine trying to put 2000 pounds of side load into a tire while measuring toe deflection! At Morse Measurements, K&C measurements are made easy thanks to our state-of-the-art Anthony Best Dynamics K&C test rig, the first of its kind to be independently operated and made publicly available in North America.

The AB Dynamics K&C test machine at Morse Measurements is specifically designed to displace and load a vehicle in our facility in ways that would be very difficult to do otherwise.

How Does K&C Testing Work?

This test rig clamps to the vehicle chassis from the underside and moves it in vertical bounce, roll, and pitch. The tires stay in contact with a level “road plane” at four individual wheel pads. These wheel pads can maintain zero scrub force (through continuous feedback force control) or they can introduce ground-level forces to simulate braking, acceleration, and cornering loads at the tire contact patches. Precision digital encoders and load cells measure tire loads and wheel orientations at all times.

All these forces and displacements are applied slowly (quasi-statically) to capture suspension force-displacement relationships and friction. By measuring all these things at Morse Measurements – where everything is accessible and repeatable – you can reduce a lot of the guesswork and costs associated with on-road/track test sessions.

Once a test is complete, there’s a myriad of information and insights available to us about the vehicle’s suspension. We can categorize the characteristics and tests into kinematics and compliance.

Suspension Kinematics

Kinematics refers to the suspension geometry. Common kinematic characteristics are wheel toe and camber, bump steer, track width and wheelbase change in bounce/roll, and roll steer. These characteristics are crucial when comparing a prototype build to the intended design, when evaluating the ride and handling of the vehicle, or when building an accurate vehicle model.

We use a suite of tests to comprehensively evaluate the kinematics of the suspension. Here are a few of the most common kinematics tests we run:

- Bounce test: The table is moved up and down with the pads maintaining zero scrub forces and aligning moments. We use it to determine wheel rates, ride rates, bump steer/camber/caster, wheel center movements, kinematic roll center height, virtual swing arm angle/length, and a lot more.

- Roll test: The table is rotated about a longitudinal axis and the wheel pads maintain zero scrub forces and aligning moments. We use roll tests to determine roll steer, axle steer, roll stiffness, roll stiffness distribution, static roll weight transfer coefficient, wheel center movements, and a lot more.

- Steering test: This time, the table is held fixed while the steering robot sweeps the handwheel through its range of displacement. Loads and displacement are then measured at the front wheels. We use the steering test to determine kingpin axis properties, mechanical trail, Ackermann percent, instantaneous steering ratio, and a lot more.

- Click here to explore more tests.

Suspension Compliance

In this context, compliance is the inverse of stiffness. It has to do with how much suspension components flex or move under load. This information is essential for a complete understanding of a suspension system.

Here are a few of the tests we use to measure compliance characteristics:

- Lateral compliance test: In this test, the table is held fixed while lateral forces are driven into the tires through the wheel pads. Through this test, we determine axle steer, lateral toe stiffness, lateral camber stiffness and more.

- Longitudinal compliance test: Similar to the lateral test, in the longitudinal compliance test the table is held fixed while longitudinal forces are driven into the tires through the wheel pads. Through this test, we determine longitudinal toe stiffness, camber stiffness, and anti-dive/anti-squat angles, among other things.

- Aligning torque test: In this test the table holds the chassis fixed while aligning moments are applied to the tires through the pads. We determine characteristics such as toe stiffness, tire aligning stiffness, hysteresis, and steering torque feedback from this test.

- Click here to explore more tests.

No other company can provide me the detailed understanding of the dynamics of the suspension and compliance of the components like Morse Measurements can with their K&C rig.

How Do You Plan a K&C Test?

We help our clients plan their K&C tests around the goals they want to accomplish. We’ve seen some common trends emerge over the past 15 years, here’s a few common goals:

- Get data necessary for CarSim or other vehicle dynamics model.

- Evaluate the quality and effectiveness of a prototype build.

- Benchmark competitor vehicles to evaluate their design decisions.

- Compare the performance of different suspension components.

- Tune bushings, anti-roll bars, etc. to achieve desired vehicle targets.

Learn more about planning a K&C test to meet your goals.

Please contact us to find out more about K&C testing, request a free quote, or ask a question.

Got Questions About K&C Testing?

K&C testing has massive potential for your vehicle development program..but understanding that potential and how to make use of it isn’t always straightforward. If you’ve got some questions about K&C testing then check out our frequently asked questions page, or watch a free webinar answering the most common questions.

Kinematics and Compliance (K&C) Testing:

Kinematics and compliance testing (K&C testing) is a type of quasi-static suspension testing that applies realistic loads and displacements to a vehicle’s chassis and tires to determine suspension geometry and stiffness characteristics.

Let’s break that down.

K&C testing is a special type of vehicle suspension testing.

The “K” stands for Kinematics – This is the suspension geometry (toe, camber, etc.). The “C” stands for Compliance – This is the suspension stiffness (i.e. how far do things bend when road loads come up through the tires).

Measuring suspension kinematics and compliance characteristics is very difficult without the proper tools. Imagine trying to put 2000 pounds of side load into a tire while measuring toe deflection! At Morse Measurements, K&C measurements are made easy thanks to our state-of-the-art Anthony Best Dynamics K&C test rig, the first of its kind to be independently operated and made publicly available in North America.

The AB Dynamics K&C test machine at Morse Measurements is specifically designed to displace and load a vehicle in our facility in ways that would be very difficult to do otherwise.

How Does K&C Testing Work?

This test rig clamps to the vehicle chassis from the underside and moves it in vertical bounce, roll, and pitch. The tires stay in contact with a level “road plane” at four individual wheel pads. These wheel pads can maintain zero scrub force (through continuous feedback force control) or they can introduce ground-level forces to simulate braking, acceleration, and cornering loads at the tire contact patches. Precision digital encoders and load cells measure tire loads and wheel orientations at all times.

All these forces and displacements are applied slowly (quasi-statically) to capture suspension force-displacement relationships and friction. By measuring all these things at Morse Measurements – where everything is accessible and repeatable – you can reduce a lot of the guesswork and costs associated with on-road/track test sessions.

Once a test is complete, there’s a myriad of information and insights available to us about the vehicle’s suspension. We can categorize the characteristics and tests into kinematics and compliance.

Suspension Kinematics

Kinematics refers to the suspension geometry. Common kinematic characteristics are wheel toe and camber, bump steer, track width and wheelbase change in bounce/roll, and roll steer. These characteristics are crucial when comparing a prototype build to the intended design, when evaluating the ride and handling of the vehicle, or when building an accurate vehicle model.

We use a suite of tests to comprehensively evaluate the kinematics of the suspension. Here are a few of the most common kinematics tests we run:

- Bounce test: The table is moved up and down with the pads maintaining zero scrub forces and aligning moments. We use it to determine wheel rates, ride rates, bump steer/camber/caster, wheel center movements, kinematic roll center height, virtual swing arm angle/length, and a lot more.

- Roll test: The table is rotated about a longitudinal axis and the wheel pads maintain zero scrub forces and aligning moments. We use roll tests to determine roll steer, axle steer, roll stiffness, roll stiffness distribution, static roll weight transfer coefficient, wheel center movements, and a lot more.

- Steering test: This time, the table is held fixed while the steering robot sweeps the handwheel through its range of displacement. Loads and displacement are then measured at the front wheels. We use the steering test to determine kingpin axis properties, mechanical trail, Ackermann percent, instantaneous steering ratio, and a lot more.

- Click here to explore more tests.

Suspension Compliance

In this context, compliance is the inverse of stiffness. It has to do with how much suspension components flex or move under load. This information is essential for a complete understanding of a suspension system.

Here are a few of the tests we use to measure compliance characteristics:

- Lateral compliance test: In this test, the table is held fixed while lateral forces are driven into the tires through the wheel pads. Through this test, we determine axle steer, lateral toe stiffness, lateral camber stiffness and more.

- Longitudinal compliance test: Similar to the lateral test, in the longitudinal compliance test the table is held fixed while longitudinal forces are driven into the tires through the wheel pads. Through this test, we determine longitudinal toe stiffness, camber stiffness, and anti-dive/anti-squat angles, among other things.

- Aligning torque test: In this test the table holds the chassis fixed while aligning moments are applied to the tires through the pads. We determine characteristics such as toe stiffness, tire aligning stiffness, hysteresis, and steering torque feedback from this test.

- Click here to explore more tests.

How Do You Plan a K&C Test?

We help our clients plan their K&C tests around the goals they want to accomplish. We’ve seen some common trends emerge over the past 15 years, here’s a few common goals:

-

Get data necessary for CarSim or other vehicle dynamics model.

-

Evaluate the quality and effectiveness of a prototype build.

-

Benchmark competitor vehicles to evaluate their design decisions.

-

Compare the performance of different suspension components.

-

Tune bushings, anti-roll bars, etc. to achieve desired vehicle targets.

Learn more about planning a K&C test to meet your goals.

Please contact us to find out more about K&C testing, request a free quote, or ask a question.

Got Questions About K&C Testing?

K&C testing has massive potential for your vehicle development program..but understanding that potential and how to make use of it isn’t always straightforward. If you’ve got some questions about K&C testing then check out our frequently asked questions page, or watch a free webinar answering the most common questions.

Get in touch:

Call Now: 704.638.6515

Call Now:

704.638.6515

1163 Speedway Blvd.,

Salisbury, NC 28146

Phone: 704.638.6515

Fax: 704.638.6516

Info@MorseMeasurements.com

© 2025 Morse Measurements | Powered by Miller Davis

1163 Speedway Blvd., Salisbury, NC 28146

Phone: 704.638.6515

Fax: 704.638.6516

Info@MorseMeasurements.com

© 2025 Morse Measurements | Powered by Miller Davis