What Exactly is K&C Testing?

What Exactly is K&C Testing?

Let’s face it, there’s a lot of confusion about kinematics and compliance testing (K&C testing):

- Is that KNC testing?

- Or is it KFC testing?

- Isn’t that just a pull-down rig?

- Maybe a 7-post rig?

- You just get ride rates from it, right?

We get it, it’s a sophisticated type of suspension measurement that not everyone is familiar with. These common confusions are completely understandable…well, at least most of them:

First off, we need to address what K&C testing is not.

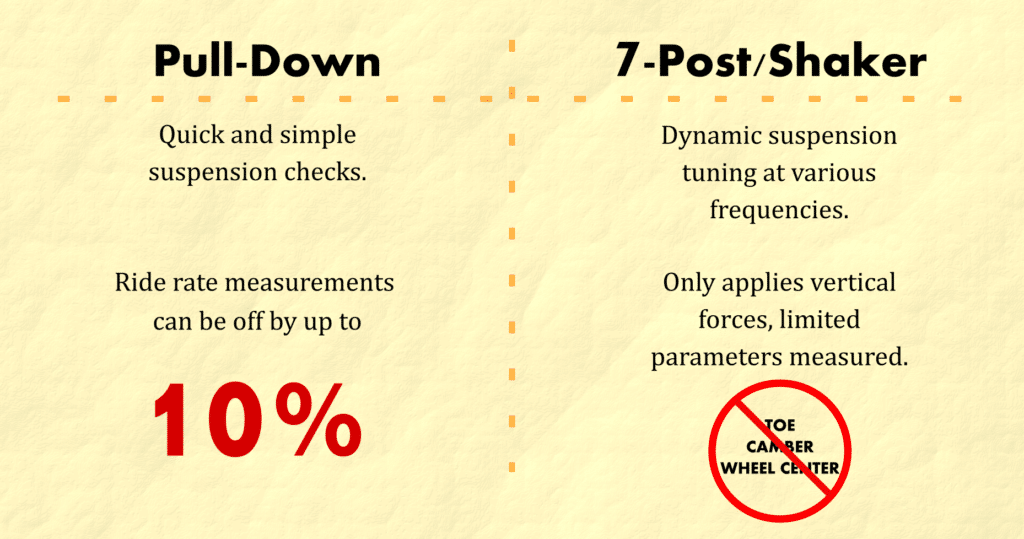

It’s not pull-down testing

A pull-down rig is a powerful tool for quick suspension measurements and checks; it’s great for checking bump stop engagement, and suspension clearances or other interference and can be used to calculate the ride rates.

However, a pull-down rig has some limitations. Because these rigs don’t remove tire scrub forces from the calculated ride rates they are not accurate. They can easily be 10% off.

It’s not 7-post shaker testing

K&C testing is commonly confused with 7-post shaker testing. In 7-post testing, vertical loads are applied to the vehicle at high frequencies to learn about the dynamic response of the vehicle. This information is very helpful for tuning dampers but again plays a limited role in fingerprinting a suspension. Because only vertical loads are applied–no braking, cornering, or tractive loads–effects resulting from jacking forces can’t be measured. Because toe, camber, and wheel center motion aren’t measured, suspension geometry and stiffness characteristics cannot be determined.

The wordy definition:

Now we come to it, the wordy definition of K&C testing you knew was coming:

Kinematics and compliance testing is a type of quasi-static suspension testing that applies realistic loads and displacements to vehicle’s chassis and tires to determine suspension geometry and stiffness characteristics.

Right, with that out of the way, let’s look at how it works.

How it works

The K&C test rig at Morse Measurements is one produced by Anthony Best Dynamics, in the UK. It is an SPMM 4000. SPMM stands for Suspension Parameter Measurement Machine. Of interest, it’s not hydraulic. Instead, it uses electric motors and actuators to move the vehicle and apply forces. These allow for much more precise and consistent motion control.

The K&C machine consists of a center table that actuates in vertical bounce (up and down), roll (rotation along a longitudinal axis), and pitch (rotation along a lateral axis) along with four wheel pads. Each wheel pad has four multi-axis Kistler load cells and can drive lateral, longitudinal, and aligning torque loads into the tire.

To test a vehicle, we clamp the chassis to the center table, typically via the vehicle’s pinch welds. Each tire rests on its corresponding wheel pad, where we connect several string encoders to the wheel to measure the wheel’s orientation (camber and toe) and displacement (wheel center movement). We also connect a steering robot to the steering wheel; the robot can apply and measure handwheel torque and displacement throughout tests.

Once it’s all set up, realistic loads are applied through the table’s movements, the wheel pads, the steering robot, or some combination of the three.

Once a test is complete, there’s a myriad of information and insights available to us about the vehicle’s suspension. We can categorize the characteristics and tests into two categories: kinematics and compliance (bet you didn’t see that one coming).

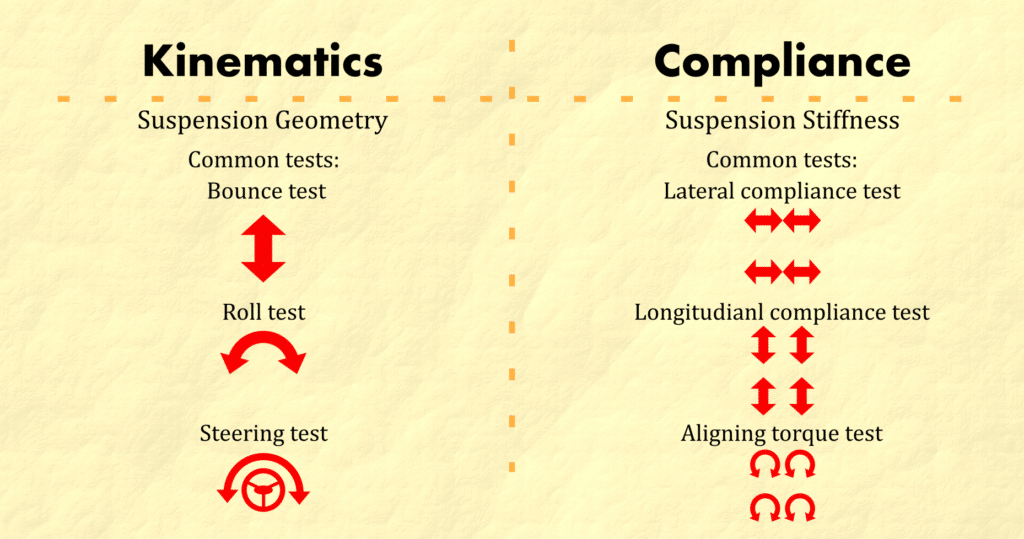

Kinematics

Kinematics refers to the suspension geometry. Common kinematic characteristics are wheel toe and camber, bump steer, track width and wheelbase change in bounce/roll, and roll steer. These characteristics are crucial when comparing a prototype build to the intended design, when evaluating the ride and handling of the vehicle, or when building an accurate vehicle model.

We use a suite of tests to comprehensively evaluate the kinematics of the suspension. Here are a few of the most common kinematics tests we run:

- Bounce test:The table is moved up and down with the pads maintaining zero scrub forces and aligning moments. We use it to determine wheel rates, ride rates, bump steer/camber/caster, wheel center movements, kinematic roll center height, virtual swing arm angle/length, and a lot more.

- Roll test: The table is rotated about a longitudinal axis and the wheel pads maintain zero scrub forces and aligning moments. We use roll tests to determine roll steer, axle steer, roll stiffness, roll stiffness distribution, static roll weight transfer coefficient, wheel center movements, and a lot more.

- Steering test: This time, the table is held fixed while the steering robot sweeps the handwheel through its range of displacement. Loads and displacement are then measured at the front wheels. We use the steering test to determine kingpin axis properties, mechanical trail, Ackermann percent, instantaneous steering ratio, and (you guessed it) a lot more.

Compliance

When we talk about compliance we don’t have to pull out an enormous book of codes and regulations. We’re talking about a different kind of compliance. In this context, compliance is the inverse of stiffness. It has to do with how much suspension components flex or move under load. This information is essential for a complete understanding of a suspension system.

Here are a few of the tests we use to measure compliance characteristics:

- Lateral compliance test:In this test, the table is held fixed while lateral forces are driven into the tires through the wheel pads. Through this test, we determine axle steer, lateral toe stiffness, lateral camber stiffness and more.

- Longitudinal compliance test:Similar to the lateral test, in the longitudinal compliance test the table is held fixed while longitudinal forces are driven into the tires through the wheel pads. Through this test, we determine longitudinal toe stiffness, camber stiffness, and anti-dive/anti-squat angles, among other things.

- Aligning torque test: In this test the table holds the chassis fixed while aligning moments are applied to the tires through the pads. We determine characteristics such as toe stiffness, tire aligning stiffness, hysteresis, and steering torque feedback from this test.

What’s the point?

All this data and insight is all well and good, but what’s the point of K&C testing? Put another way, what goals do engineers have when they come to test?

There’s a host of reasons.

- Get data necessary for CarSim or other vehicle dynamics model.

- Evaluate the quality and effectiveness of a prototype build.

- Benchmark competitor vehicles to evaluate their design decisions.

- Compare the performance of different suspension components.

- Tune bushings, anti-roll bars, etc. to achieve desired vehicle targets.

Check out our article here about common K&C goals and how we go about reaching those goals.

Maybe it’s not so complicated after all

Hopefully, we’ve demystified suspension kinematic and compliance testing a little bit for you. It’s a powerful form of suspension testing that can provide you a wealth of knowledge about a vehicle’s suspension design and ride and handling performance. It’s an important tool in your toolbox for evaluating design choices, making improvements, and building an accurate simulation.

And it has nothing to do with fried chicken.

Call Now: 704.638.6515

Call Now:

704.638.6515

1163 Speedway Blvd.,

Salisbury, NC 28146

Phone: 704.638.6515

Fax: 704.638.6516

Info@MorseMeasurements.com

© 2025 Morse Measurements | Powered by Miller Davis

1163 Speedway Blvd., Salisbury, NC 28146

Phone: 704.638.6515

Fax: 704.638.6516

Info@MorseMeasurements.com

© 2025 Morse Measurements | Powered by Miller Davis